WEG saves time and increases reliability by integrating DEIF controller

WEG, one of the world’s largest industrial electric systems supplier, wanted to have more configuration options/features for genset protection to increase its competitiveness in the marine market. Support, flexibility and reliability were some of the essential parameters when searching for a new partner.

WEG SA was founded in Brazil in 1961 and has rapidly grown to be a global key player with an annual revenue in 2019 of 13.348 million R$ (3.20 billion USD) and more than 31,000 employees worldwide. WEG is divided into five business units: Motors, Automation, Energy, Transmission & Distribution and Coatings. The Brazilian giant produces more than 1,700,000 litres of liquid coating every month, plus it assembles 2.1 million electronic boards yearly and has produced impressive 250 million motors in total.

Covering 1,000,000 m2 or what equals almost 151 soccer fields, WEG headquarters in Jaraqua do Sul is truly impressive. 17,000 people work on the premises in southern Brazil, and everywhere you meet dedicated and highly skilled professionals. WEG employs more than 3,000 engineers worldwide and has manufactured more than 1 billion automation products. With WEG, all numbers are overwhelming, and the fast-growing company is keen on continuing fast and sustainable development. WEG creates quality products and efficient solutions and to succeed, strong partnerships are necessary.

Multi-functional controller saves space and increases flexibility and reliability

To make the company independent and able to provide its customers with the best service possible, it produces many by-products, counting everything from contacts til pallets. The organisation is top-tuned, and the demand for quality and competitive solutions was also the reason why WEG started looking for a new partner that could supply automation products for its marine solutions.

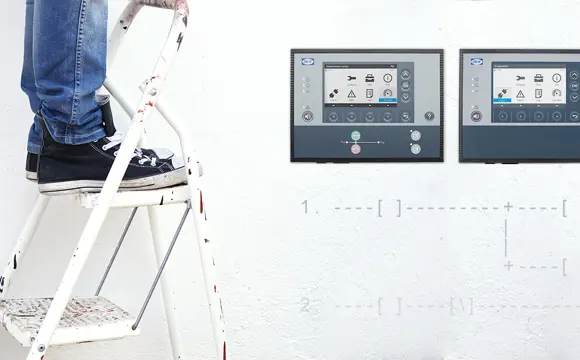

Searching the market for a suitable partner, the WEG team was introduced to DEIF’s PPU 300 protection and paralleling controller. WEG appreciates the fact that the PPU 300 controller both compiles genset protection and control.

For WEG, the PPU 300 comprises all these functions, saving both space on the switchboard and enables the company to offer a solution that is more flexible and reliable.

Easy configuration saves time for engineering and commissioning

For the controller to get through the eye of a needle, it was sent to WEG’s engineering team to ensure that it would live up to WEG’s quality standards and demands.

WEG’s engineering team analysed the controller and found that it would match their needs in terms of user-friendliness and configuration options.

WEG’s engineers verified that the PPU 300 was very easy to configure and that incorporating the controller to WEG’s solution would save time for engineering and commissioning marine solutions.

Training and support is essential

To get properly introduced to the controller, DEIF’s Product Manager Hamid Mohammed Haddaj, travelled to Brazil to conduct a one-week training to the WEG’s engineering and support team.

The engineering team found the training very good and learned how to work with the PPU 300 controller. WEG’s service team also participated in the training to be able to support WEG’s customers directly.

Product Manager Hamid was impressed by the WEG teams expertise and could after the training conclude that the team was autonomous and needed only very little guidance to configure the controller. “The guys in WEG’s engineering and service team are very professional and working with them is both inspiring and challenging as they are on top of their game. From my side, the process has run smoothly, and the team from WEG has only needed a minimum of support to make a powerful application for the project”, says Hamid.

Having completed the training session, WEG’s team can now make all future configurations and so far, WEG has included the PPU 300 controller on two offshore supply vessels (OSV) and a diving support vessel (DSV). The solution was well-received, and the client was already familiar with the DEIF brand and believed that interaction between WEG and DEIF would be beneficial.

More vessels will follow

Based on the feedback from the engineering team and the commissioning team, WEG expects the PPU 300 controller also to be integrated into future projects.

WEG is currently facing new projects, among others, an ROV & Diving Support Vessel with DP2 (dynamic positioning), river pusher, tug boats, and a series of new vessels.

-

Contact us to discuss your options

- 90 years of energy pioneering

- Manufactured at the highest standards

- Superior quality

- Unmatched service and support

- Made in Denmark